black rubber stopper /coating machine for 17 years

Basic Info

Model No.: wsr - rubber stopper-015

Product Description

BLACK RUBBER EPDM / black rubber stopper /coating machine for 17 years

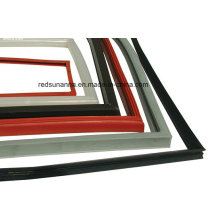

Good resistance to oil, acid and alkali,cold hot resistant and ageing resistance performance. Can be directly cut into various shapes of sealing gaskets, widely used in pharmaceutical, electronic, chemical, antistatic, flame retardant, food industry, etc It also has good abrasion resistance, ageing resistance and air tightness, thus in the rubber industry is used widely.

Good resistance to oil, acid and alkali,cold hot resistant and ageing resistance performance. Can be directly cut into various shapes of sealing gaskets, widely used in pharmaceutical, electronic, chemical, antistatic, flame retardant, food industry, etc It also has good abrasion resistance, ageing resistance and air tightness, thus in the rubber industry is used widely.

we produce the epdm automotive molded rubber product accord with the eu environmental standards and the eu food grade standards.

2.The rubber material main performance data Product Working temperature Working pressure Common specification

NBR -20°C~110°C PN<=16MPa DN15~DN400

FRB -20°C~200°C PN<=16MPa DN15~DN400

NR -50°C~80°C PN<=16MPa DN15~DN400

CR -20°C~100°C PN<=16MPa DN15~DN400

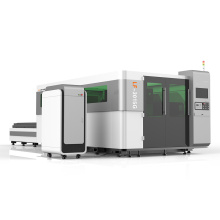

EPDM -57°C~176°C presure<2.5MPa DN15~DN400 WMQ -100°C~300°C presure<3.0MP a DN15~DN400 WSR's mold workshop Description: 1. WSR have 12 CNC machines, 3EDM machines, we can make over 100sets Rubber Mould per month. 2. Compression/transfer/injection(both hot runner and cold runner are available) types. 3. The common mold steel we use are NAK80, P20, 4140, S50C 4. We have 15years experience in making rubber moulds, especially for Rubber Molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China. 5. We have our own Rubber Products workshop, we can test the mold before ship the mold to customer. 6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies. 7. Experience sales representative discuss with customer about the mold design prior to mold making. 8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days. 9. WSR can help customer to run mass production. WSR's rubber workshop Description: Description: 1.Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more) 2.Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance 3.Color: for rubber, usually black, for silicone, can be in any color as you want 4.Machine type: 50 to 400 tons 5.Molding service: we have our own mold workshop which have 12 sets CNC machines and provide 6.compression/transfer/injection rubber molds 7.ISO9000 and TS16949 certificated factory 8.Mold/samples lead-time: 8.1 For prototype mold, usually in 7days 8.2 For mass production mold, usually in 2 weeks 8.3 For some special molds, can be in 30days, especially for some automotive rubber molds 8.4 Small orders are welcomed company pictures:

Contact us if you need more details on Rubber Stopper for Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Black Rubber Stopper、Rubber Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Rubber Stopper for Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Black Rubber Stopper、Rubber Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Good resistance to oil, acid and alkali,cold hot resistant and ageing resistance performance. Can be directly cut into various shapes of sealing gaskets, widely used in pharmaceutical, electronic, chemical, antistatic, flame retardant, food industry, etc It also has good abrasion resistance, ageing resistance and air tightness, thus in the rubber industry is used widely.

Good resistance to oil, acid and alkali,cold hot resistant and ageing resistance performance. Can be directly cut into various shapes of sealing gaskets, widely used in pharmaceutical, electronic, chemical, antistatic, flame retardant, food industry, etc It also has good abrasion resistance, ageing resistance and air tightness, thus in the rubber industry is used widely.we produce the epdm automotive molded rubber product accord with the eu environmental standards and the eu food grade standards.

2.The rubber material main performance data Product Working temperature Working pressure Common specification

NBR -20°C~110°C PN<=16MPa DN15~DN400

FRB -20°C~200°C PN<=16MPa DN15~DN400

NR -50°C~80°C PN<=16MPa DN15~DN400

CR -20°C~100°C PN<=16MPa DN15~DN400

EPDM -57°C~176°C presure<2.5MPa DN15~DN400 WMQ -100°C~300°C presure<3.0MP a DN15~DN400 WSR's mold workshop Description: 1. WSR have 12 CNC machines, 3EDM machines, we can make over 100sets Rubber Mould per month. 2. Compression/transfer/injection(both hot runner and cold runner are available) types. 3. The common mold steel we use are NAK80, P20, 4140, S50C 4. We have 15years experience in making rubber moulds, especially for Rubber Molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China. 5. We have our own Rubber Products workshop, we can test the mold before ship the mold to customer. 6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies. 7. Experience sales representative discuss with customer about the mold design prior to mold making. 8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days. 9. WSR can help customer to run mass production. WSR's rubber workshop Description: Description: 1.Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more) 2.Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance 3.Color: for rubber, usually black, for silicone, can be in any color as you want 4.Machine type: 50 to 400 tons 5.Molding service: we have our own mold workshop which have 12 sets CNC machines and provide 6.compression/transfer/injection rubber molds 7.ISO9000 and TS16949 certificated factory 8.Mold/samples lead-time: 8.1 For prototype mold, usually in 7days 8.2 For mass production mold, usually in 2 weeks 8.3 For some special molds, can be in 30days, especially for some automotive rubber molds 8.4 Small orders are welcomed company pictures:

Contact us if you need more details on Rubber Stopper for Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Black Rubber Stopper、Rubber Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Rubber Stopper for Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Black Rubber Stopper、Rubber Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Molded Rubber Products > Auto Rubber Part

Premium Related Products

Other Products

Hot Products

Molded Silicone Rubber ProductsNBR rubber washerscustom molded NBR rubber membranetransfer molded Rubber grommetrubber bend sealCustom FKM/EPDM Rubber gasket moldinganti-slip Custom rubber mat OEM orders onlyNBR/EPDM/CR/FKM rubber sealing by OEMoilfield rubber Hi-Temp Type packingCustom rubber to metal bonded products-A021Rubber RC tire for racing carrubber roller for industrial, office, home appliance useNitrile rubber o-ringinjection silicone Rubber MouldHigh quality Silicone Rubber product with competitive priceAutomotive rubber dust preventive cover